PLA coated paper is a bio-based functional paper material designed to combine the structural advantages of paper with the sealing and barrier properties of polylactic acid (PLA). It is increasingly discussed as an alternative to conventional PE coated paper, particularly in applications where sustainability considerations and regulatory pressure are becoming more important.

However, PLA coated paper is not a direct one-to-one replacement for PE in all scenarios. Its performance profile, processing window, and end-of-life conditions require careful technical evaluation. This article explains what PLA coated paper is, how PLA behaves as a coating material, its real-world performance boundaries, compostability conditions, typical use cases, and a practical buying checklist for sourcing.

Quick Definition

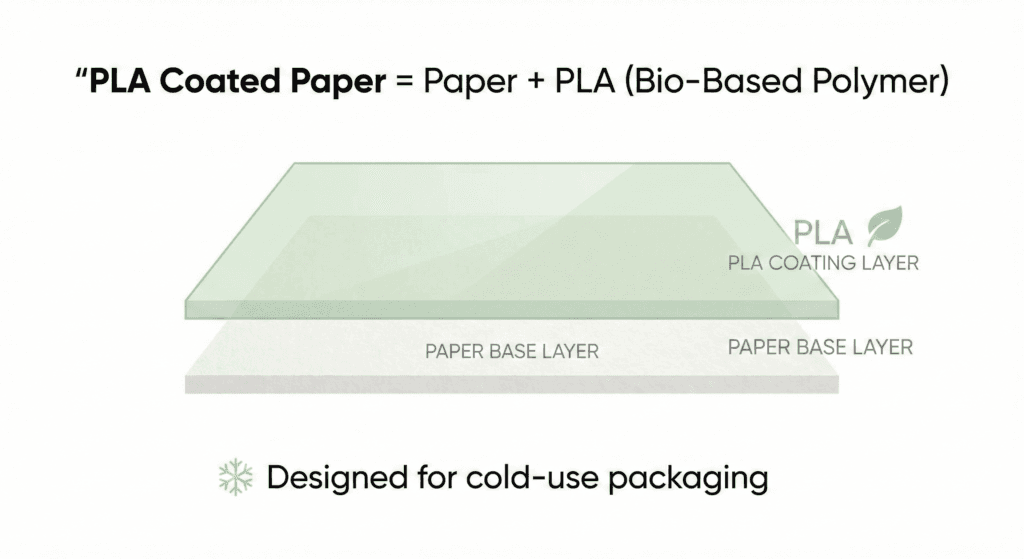

PLA coated paper = paper substrate + PLA coating or laminated layer

PLA (polylactic acid) is a bio-based thermoplastic polymer, typically applied to paper through extrusion coating or lamination. The PLA layer forms a continuous film that provides:

Basic moisture resistance

Heat sealability

Improved surface integrity

The paper substrate provides stiffness, printability, and mechanical strength, while PLA adds functional properties similar to conventional plastics—within a narrower processing and performance window.

PLA Basics

Raw Material Origin

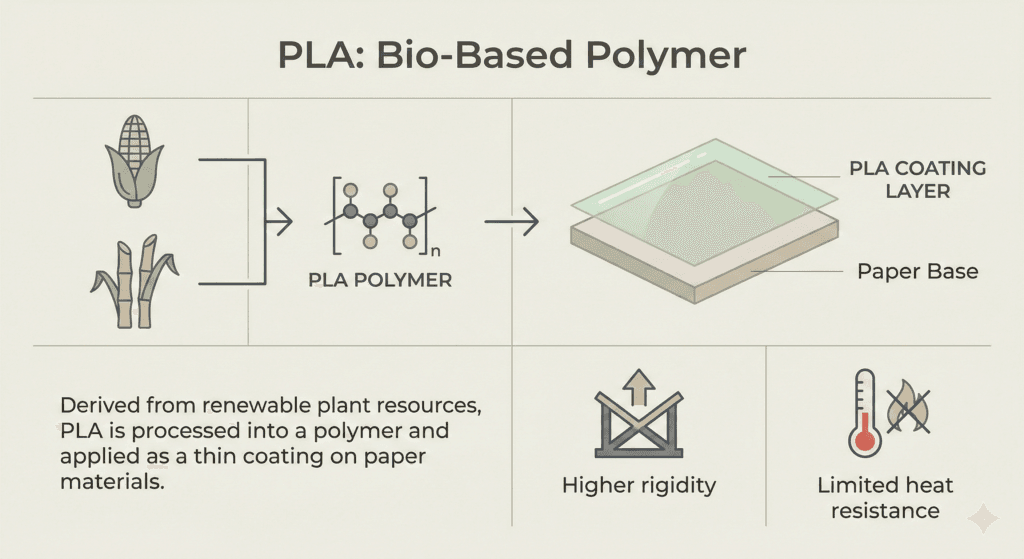

PLA is derived from renewable agricultural resources such as:

Corn starch

Sugarcane

Cassava

Through fermentation and polymerization, plant-based sugars are converted into lactic acid and then into PLA resin. From a material sourcing perspective, PLA is considered bio-based, meaning its carbon content originates from renewable biomass rather than fossil fuels.

Material Characteristics

From an engineering standpoint, PLA has distinct physical properties:

Higher rigidity compared to LDPE

Lower flexibility than many petroleum-based plastics

Relatively low heat deformation temperature

These characteristics influence how PLA coated paper performs during converting, filling, and end use. PLA typically behaves more like a rigid thermoplastic than a soft sealing resin, which affects forming tolerance and sealing robustness.

PLA Coated Paper Performance Profile

Understanding the realistic performance limits of PLA coated paper is critical for correct material selection.

Heat Sealability

PLA can be heat sealed, but the sealing window is narrower than PE. Seal strength is highly sensitive to:

Temperature

Dwell time

Pressure

Inconsistent sealing parameters may lead to brittle seals or incomplete bonding, especially at high production speeds.

Water and Moisture Resistance

PLA provides a basic moisture barrier, sufficient for short-term contact with cold or room-temperature liquids. However, its long-term water resistance is generally lower than PE, particularly under elevated temperatures.

Heat Resistance and Use Boundaries

PLA coated paper has clear thermal limitations:

Suitable for cold beverages

Limited suitability for warm-fill applications

Not recommended for high-temperature hot drinks or prolonged heat exposure

Material selection should always be validated through real-use testing rather than assumed equivalency with PE.

Compostability Explained Of PLA Coated Paper (Without Overstatement)

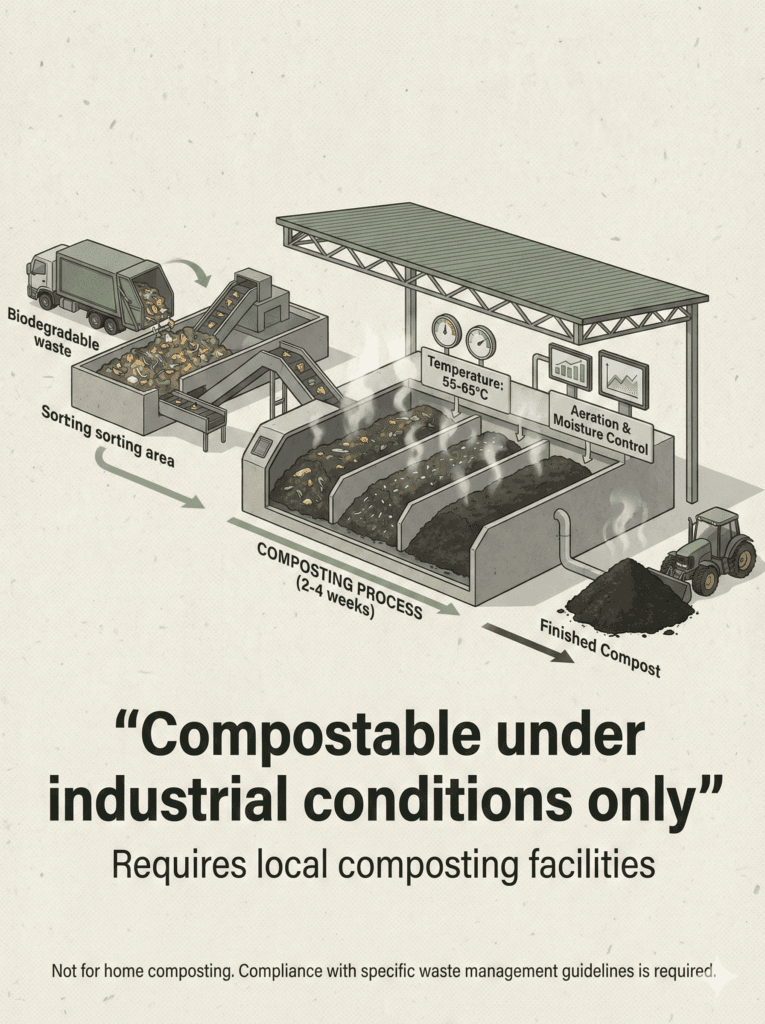

PLA coated paper is often described as “compostable,” but this term requires precise clarification.

Industrial Composting Conditions

PLA is compostable only under industrial composting conditions, which typically include:

Controlled temperatures (around 58–60°C)

High humidity

Active microbial environments

Defined residence times

Under these conditions, PLA can break down into water, carbon dioxide, and biomass.

Certifications and Standards Of PLA Coated Paper

Common certifications include:

EN 13432 (EU)

ASTM D6400 (US)

These certifications apply to specific structures and thicknesses, not PLA as a generic material.

Infrastructure Limitations Of PLA Coated Paper

Compostability is meaningful only if suitable facilities exist locally. In regions without industrial composting systems, PLA coated paper may be treated as residual waste rather than compostable material.

Overstating compostability without acknowledging system limitations can create regulatory and reputational risks.

PLA Paper Use Cases

Due to its performance profile, PLA coated paper is best suited for select applications rather than universal replacement scenarios.

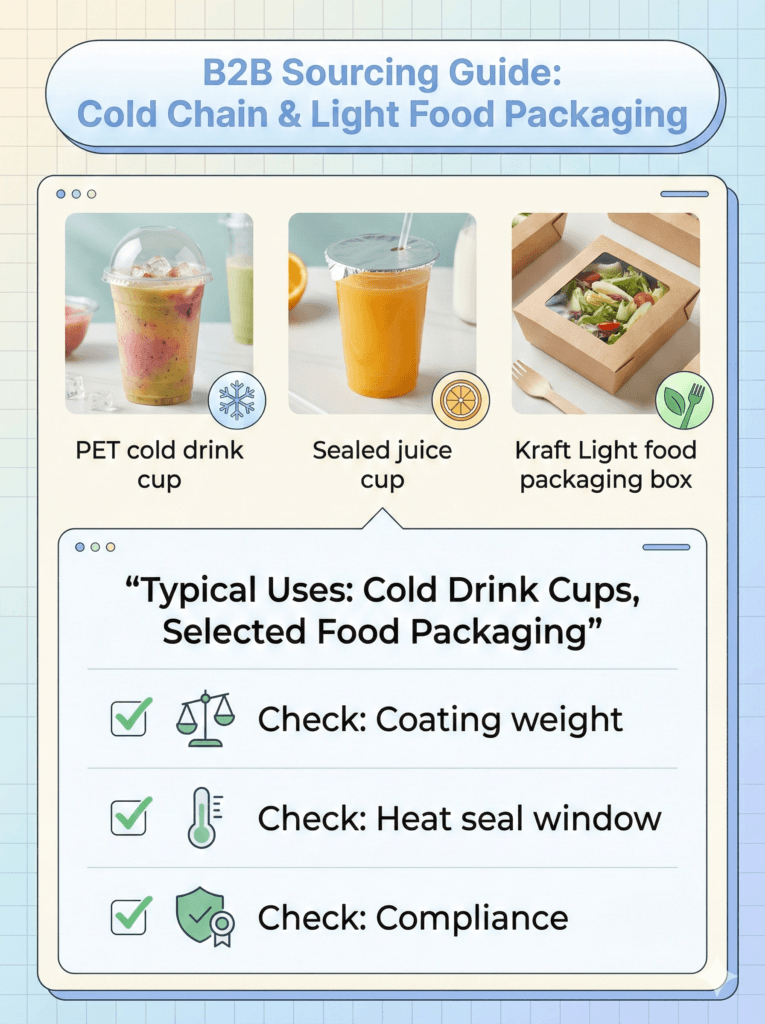

Cold Beverage Cups

PLA coated cup stock paper is commonly used for:

Cold drink cups

Smoothie cups

Juice cups

These applications align well with PLA’s moisture resistance and temperature tolerance.

Selected Food Packaging

PLA coated paper may be suitable for:

Bakery items

Dry or lightly moist foods

Short-contact food packaging

Final suitability depends on heat exposure, oil content, and storage duration.

PLA coated paper is not ideal for high-temperature soups, oily foods with long contact times, or applications requiring aggressive heat sealing.

Buying Checklist Of PLA Coated Paper

PLA Coating Weight / Thickness

Coating thickness directly affects:

Barrier performance

Heat seal strength

Compostability claims

Suppliers should specify coating weight clearly in g/m² or microns.

Heat Seal Window

Request data on:

Heat seal initiation temperature

Optimal sealing range

Seal strength under realistic production conditions

Narrow windows require tighter process control.

Heat Resistance Requirements

Clarify:

Maximum service temperature

Intended use (cold, ambient, warm)

Duration of heat exposure

Avoid assumptions based on “eco” positioning alone.

Compliance Documentation

Suppliers should provide:

Food contact compliance statements (FDA / EU)

Migration or safety declarations

Traceability of raw materials

Compostability Certifications (If Applicable)

If compostability is claimed, verify:

Applicable standards

Certification scope

Thickness and structure limitations

Regional acceptance

Conclusion

PLA coated paper represents a purpose-driven material solution, not a universal replacement for conventional PE coated paper. Its value lies in applications where bio-based sourcing and industrial compostability align with realistic performance requirements and local waste management systems.

For engineers and procurement professionals, the key to using PLA coated paper successfully is technical clarity rather than marketing assumptions. By understanding its material behavior, thermal limits, and end-of-life conditions, PLA coated paper can be applied responsibly and effectively within its appropriate use boundaries.

When evaluated and specified correctly, PLA coated paper can play a meaningful role in sustainable packaging strategies—without compromising performance or trust.