Introduction

In today’s environmentally conscious and quality-driven printing industry, surface finishing options play a pivotal role in how printed materials are perceived and preserved. Among the various coatings available, aqueous coating stands out due to its eco-friendly profile, versatility, and effective performance across different applications. This article offers an in-depth exploration of aqueous coating—its composition, comparisons with UV coatings and varnishes, applications in food packaging, water resistance capabilities, and its limitations. The goal is to provide a comprehensive understanding of why aqueous coatings are gaining traction as a smart, sustainable solution in modern printing.

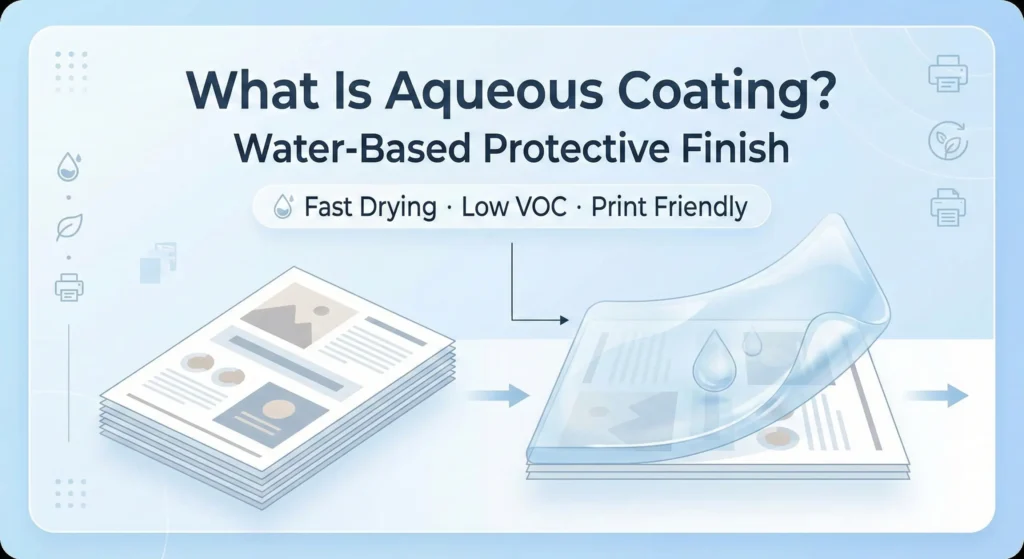

What Is an Aqueous Coating?

General Definition Of Aqueous Coating

Aqueous coating is a fast-drying, water-based clear coating applied to printed materials to protect them and enhance their appearance. It is primarily made from water mixed with polymers such as acrylics or natural resins, which harden upon drying to form a protective layer.

Use Cases

One of the most common applications of aqueous coating is in business cards, brochures, catalogs, and packaging materials. It adds a smooth finish that resists fingerprints, scuff marks, and minor abrasions. It is also compatible with post-print processes like die cutting and folding.

Foil stamping over aqueous coating is possible but requires careful planning. Some foil stamping processes may not adhere well unless the coating is specifically formulated to accept foil, or the foil is applied to an uncoated area.

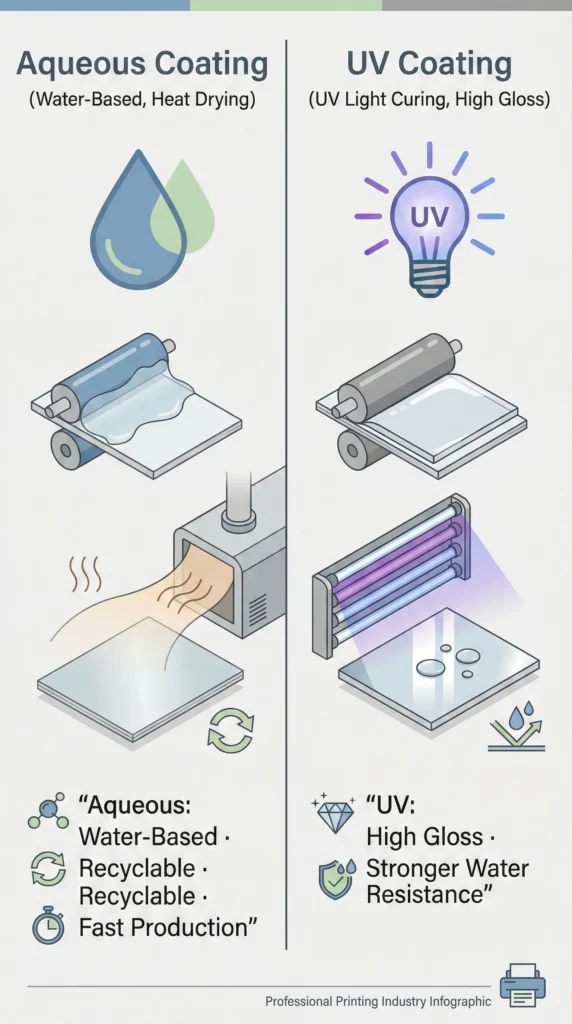

Aqueous Coating vs. UV Coating

Fundamental Differences

While both coatings serve to protect and enhance printed surfaces, aqueous and UV coatings differ significantly in formulation and curing method. Aqueous coatings are water-based and dry through evaporation and heat, whereas UV coatings are cured instantly using ultraviolet light.

Finish and Appearance

Matte aqueous coatings provide a subdued, elegant finish ideal for text-heavy documents, while high gloss UV coatings create a vibrant, reflective surface suitable for image-rich materials. The difference in sheen can influence how the final print is perceived in terms of professionalism and quality.

Functional and Technical Aspects

Drying: Aqueous coatings dry quickly via heated air, making them ideal for high-speed production lines.

Chemistry: Aqueous coatings are less chemically aggressive than UV coatings, which may contain more synthetic monomers and photoinitiators.

Application: UV coatings often require specialized equipment, while aqueous coatings can be applied with standard offset presses.

Environmental and Cost Factors

Eco-Friendliness: Aqueous coatings are generally more environmentally friendly due to their low VOC content and easier disposal.

Cost: UV coatings can be more expensive due to specialized materials and machinery.

Waste Handling: Aqueous waste is easier to treat and dispose of compared to UV waste, which can be more toxic.

Common Use Cases

UV coatings are often used where durability and gloss are critical—like magazine covers and promotional materials. Aqueous coatings are more prevalent in packaging, business collateral, and environmentally certified prints.

Limitations of UV Coating

UV coatings, despite their aesthetic appeal, can pose challenges:

Cracking on folds

Non-recyclability in some systems

Higher toxicity in manufacturing

Food Safety and Environmental Concerns

Food Safety

One of the most frequent queries is: Is aqueous coating food safe?

In general, aqueous coatings that are formulated without toxic substances and certified for indirect food contact are considered food safe. However, they are not intended for direct food contact unless specifically certified.

Toxicity and Materials

Materials: Aqueous coatings are composed of water, polymers, and small amounts of additives like waxes or anti-scuff agents.

Plastic Content: Some aqueous coatings may contain plastic-derived polymers, but there are bio-based alternatives under development.

Toxicity: Most aqueous coatings are non-toxic and meet regulatory safety standards.

Compostability and Sustainability

Aqueous coatings are often more biodegradable than UV or solvent-based coatings. Certain formulations are compostable, especially when used on paper substrates designed for compostability. Nonetheless, compostability depends on the full lifecycle analysis and specific certification.

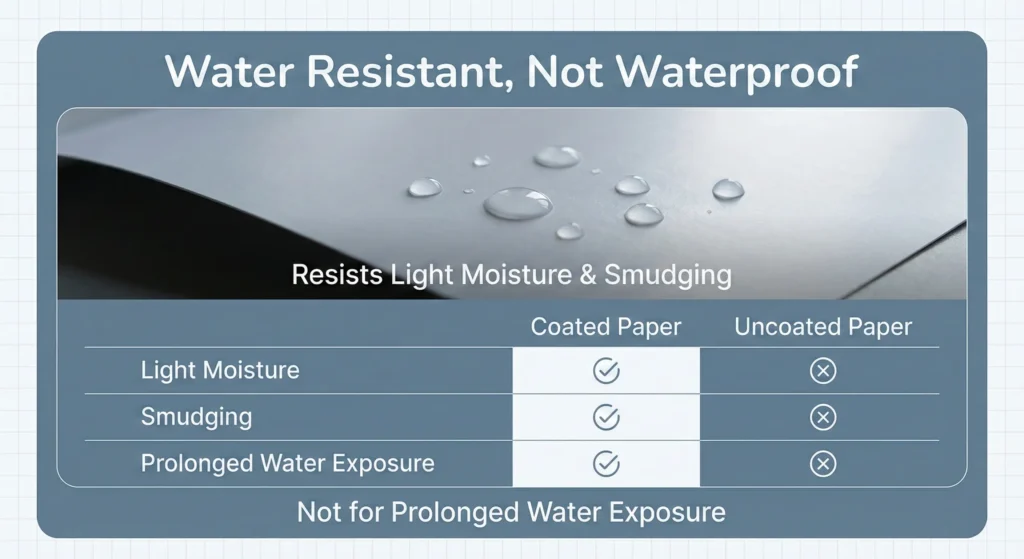

Water Resistance and Protective Capabilities

Waterproofing and Resistance

Is aqueous coating waterproof? The answer is nuanced:

Aqueous coatings offer water resistance, not full waterproofing.

They help resist smudges and light moisture but are not suitable for prolonged exposure to water.

Coated paper with aqueous finishes is often water-resistant enough for retail packaging and mailing purposes.

Coating Comparisons

Varnish vs. Aqueous: Varnish is solvent-based, yellows over time, and is less eco-friendly. Aqueous dries faster, is clearer, and more sustainable.

Elastomeric coatings, used in building applications, are waterproof but chemically and functionally different.

UV vs. Aqueous: UV coatings are more water-resistant, but less recyclable.

Practical Implications

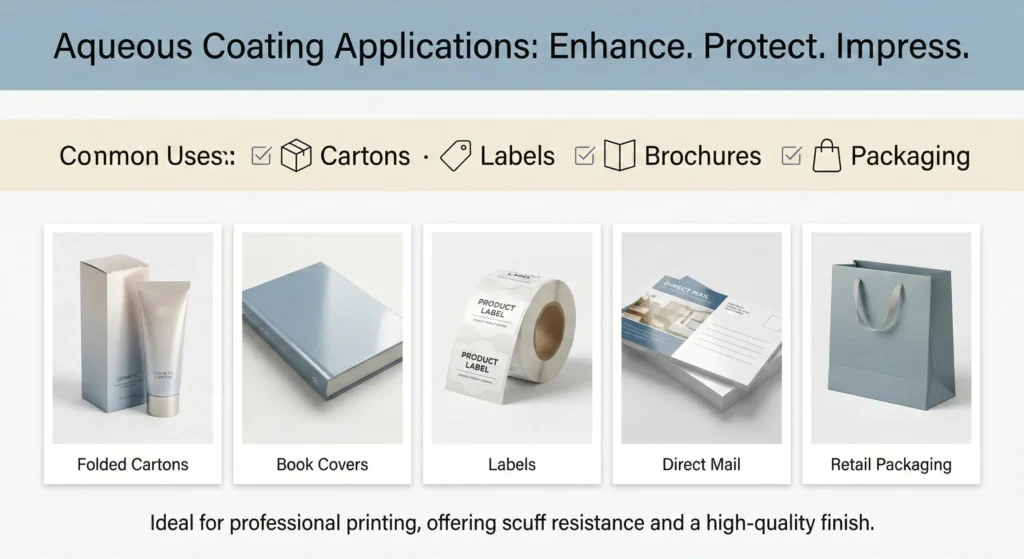

Aqueous coatings are commonly chosen for:

Folded cartons

Labels

Book covers

Direct mail

Lightly handled packaging

Their protection against abrasion, fingerprinting, and minor spills makes them ideal for most consumer goods.

Limitations and Challenges

Finishing Compatibility

Some post-printing processes such as foil stamping, embossing, or certain gluing applications can be challenging if applied over aqueous coatings. Pre-treatment or coating-free zones may be necessary.

Printing Systems

EcoTank printers, which use refillable ink systems, may not always handle coated papers effectively. The coating can interfere with ink absorption, leading to smudging or poor adhesion.

Conclusion

Aqueous coating presents a compelling combination of sustainability, functionality, and visual appeal in modern printing. Its advantages over UV coatings and varnishes include lower environmental impact, faster drying, and safer handling. While not waterproof or suitable for all finishing processes, it remains a preferred solution for businesses seeking a smart, safe, and sustainable way to enhance printed products. With ongoing advances in bio-based chemistry and compostable formulations, aqueous coatings are poised to play an even larger role in the future of eco-conscious print production.