Introduction

Overview of PET Coated Materials

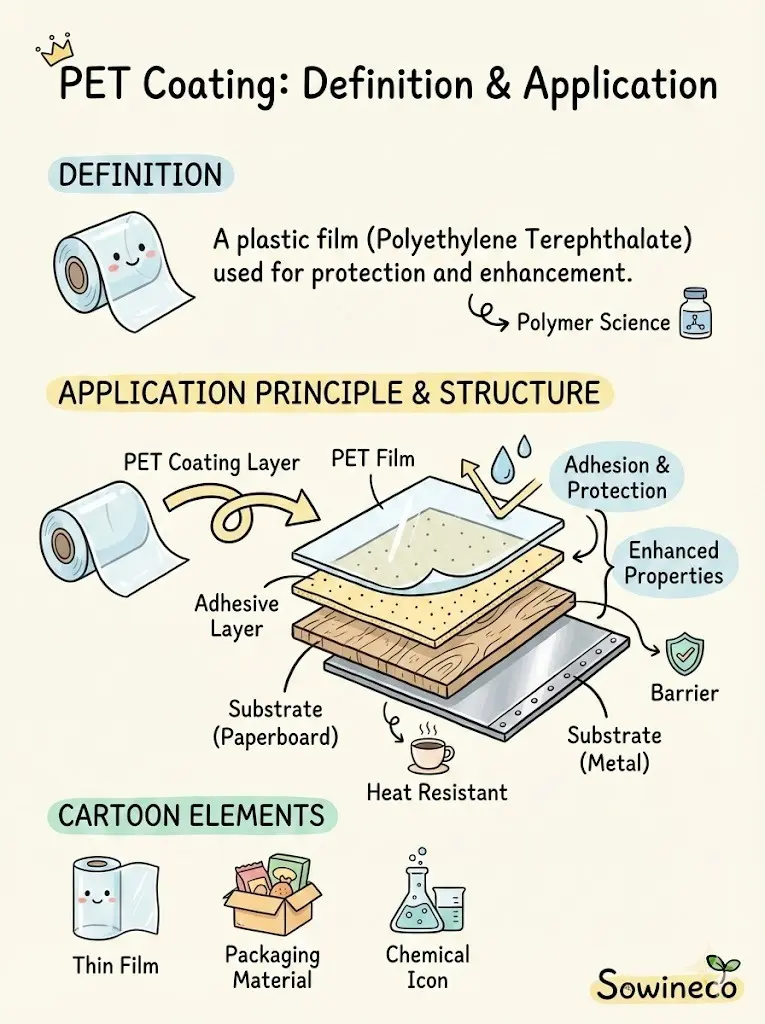

“PET coated” typically refers to a thin layer of polyethylene terephthalate (PET) applied onto another substrate—like paperboard, metal, or plastic films—to improve performance. PET coating is widely used because it creates a smooth, protective, and functional barrier without drastically changing the base material.

Importance Of PET Coated Materials in the Packaging and Material Industries

PET-coated structures show up everywhere in modern supply chains: food packaging, lidding films, labels, cartons, flexible packaging, and industrial laminates. Brands use PET coatings to achieve better moisture resistance, print quality, clarity, stiffness, and chemical resistance—especially where packaging must survive transport, refrigeration, and shelf life demands.

What is PET Coated?

Definition and Explanation of PET Coated

PET coated is a surface layer of PET added to another material to improve barrier and durability properties. The coating may be applied via lamination (bonding a PET film layer), extrusion coating, or adhesive-based coating systems, depending on end-use requirements.

Common Applications of PET Coated Materials

PET coated is commonly used in:

- Food trays and lidding (for clarity and barrier properties)

- Paperboard cartons and cups (for moisture and grease resistance)

- Metal packaging and protective layers in certain designs

- Labels and printed packaging (for gloss, durability, and scuff resistance)

- Industrial insulation, tapes, and protective films

Why PET Coated is Popular in Food Packaging

PET coated is popular in food packaging because it helps deliver:

- Strong oxygen and aroma barrier (helpful for freshness)

- High clarity and gloss (great shelf appearance)

- Mechanical strength (reduces punctures and tears in handling)

- Compatibility with many converting and printing processes

In addition, PET-based materials used in food-contact applications are commonly assessed under established regulatory frameworks, which focus on intended use conditions and migration limits.

Is PET coated the same as PET?

Distinction Between PET and PET Coated

Not exactly. PET is the polymer material itself (like PET bottles or PET film). PET coating describes PET used as a layer on top of another substrate (like paperboard or aluminum). In practice, a pure PET product is mostly PET throughout, while a PET-coated product is a composite structure.

How PET Coated is Applied to Other Materials

Common approaches include:

- Lamination: bonding PET film to paper or other films

- Extrusion coating: melting polymer and applying it as a thin layer

- Adhesive coating systems: using adhesives to bind PET layers and improve performance

This is also where sustainability can get tricky: multi-material structures are typically harder to recycle than single-material designs.

What are the advantages of PET Coated Materials?

Durability and Strength

PET offers strong tensile strength, stiffness, and puncture resistance, which helps packaging keep its shape and reduce product damage during shipping.

Resistance to Moisture and Chemicals

PET coatings can add water resistance and chemical resistance, protecting paperboard from sogginess and improving performance in refrigerated or humid conditions.

Environmental Benefits

When PET coating enables lightweight packaging, it can reduce transport emissions compared with heavier rigid alternatives. In some cases, PET coatings can also help extend shelf life, which may reduce food waste.

Sustainability of PET Coated Materials

Sustainability depends heavily on design and local end-of-life systems:

- Best case: mono-material PET structures that fit established recycling streams

- Harder case: PET-coated paperboard or multilayer packaging that requires specialized recycling or ends up as residual waste

Recycling success is often determined more by local infrastructure and sorting rules than by a material’s theoretical recyclability.

What are the downsides of PET materials?

Environmental Concerns

PET is a plastic, and plastic waste can persist in the environment when mismanaged. Even if a package is labeled “recyclable,” it may not be recycled due to collection gaps, contamination, or sorting limitations.

Disadvantages in Recycling

PET-coated composites (such as PET-coated paperboard) can be difficult to recycle because the layers may not separate cleanly. More broadly, multilayer packaging can be challenging to recycle due to mixed compositions and limited infrastructure.

Potential Health Implications

For consumers, the key question is usually food-contact safety. Safety depends on intended use conditions (temperature, contact time, food type) and whether the packaging complies with applicable migration limits and quality controls.

Can you flush microplastics out of your body?

Understanding Microplastics in PET Coated Materials

Microplastics are tiny plastic particles that can enter the body through food, beverages, and inhalation. PET-coated packaging is one of many possible contributors to overall exposure, but it is not the only source.

Human Impact and Health Concerns

Studies have detected microplastics in human stool, which suggests that at least some ingested particles can pass through the digestive system. However, the health science is still evolving: detection does not automatically mean harm, and researchers are still working out dose, particle size effects, and long-term outcomes.

Current Scientific Insights

What we can say with reasonable confidence:

- The body can excrete some ingested microplastics (stool detection supports this).

- It is still unclear how much is retained, how particles move in the body, and what exposure levels matter long-term.

Practical exposure-reduction steps (general, non-medical): avoid heating food in plastic unless it is labeled safe for that use, reduce single-use plastics when feasible, and use appropriate storage habits.

PET Coated vs Other Materials

Which is better, PP or PET?

It depends on the job:

- PET: better clarity, stiffness, and gas barrier (often preferred for premium look and freshness)

- PP: often better heat resistance and toughness for microwaving or hot-fill applications

Recycling performance also varies by region and product type. PET bottle recycling is often well-established, while PP recycling may be less consistent depending on local systems.

Is PET better than PVC?

In many packaging contexts, PET is favored because it avoids chlorine-based chemistry associated with PVC and can be more compatible with common recycling streams. PVC still appears in specialty applications where its properties are needed, but it can create problems if mixed into certain recycling processes.

What is PET Film?

How is PET Film made?

1. The Manufacturing Process of the PET Film

PET film is typically produced by:

- Polymerizing PET resin

- Extruding molten PET into a sheet

- Quenching and forming a base film

- Biaxial stretching (stretching in two directions) to improve strength and clarity

- Heat-setting for dimensional stability

The result is a smooth, strong film used across packaging, printing, and industrial applications.

Applications of PET film

1. Uses in Food Packaging, Printing

PET film is used for:

- Lidding films and laminates

- Flexible packaging layers

- Labels and graphic overlays

- Electrical insulation and protective films

What is PET Film Printing?

1. Overview of PET Film Printing Process

PET film can be printed using screen printing, digital printing, gravure, flexographic, or UV-curing systems, depending on ink type and performance requirements.

2. Benefits of PET Film for Printing

PET film is popular for printing because it offers:

- Excellent surface smoothness

- Dimensional stability

- Durability and abrasion resistance

- High clarity and strong color appearance

What is the difference between DTF and PET Film?

Defining DTF (Direct to Film) Printing

DTF printing is a process where designs are printed onto a film (often PET film), then transferred to fabric using adhesive powder and heat.

Key Differences Between DTF and PET Film

In simple terms:

- DTF is a printing and transfer method.

- PET film is the material substrate used in DTF (and many other applications).

So PET film can exist without DTF, but DTF commonly relies on PET film as the carrier layer.

Is PET Coated Safe for Consumers?

Health and Safety Consideration

In general, PET-based materials used for packaging are widely regulated. Safety depends on intended use conditions (temperature, contact time, and food type) and compliance with relevant limits and manufacturing controls.

Regulation and Standards for PET Coated Products

Regulatory frameworks vary by region. In the U.S., food contact substances are regulated for intended uses. In the EU, scientific evaluations support rules for substances used in food-contact materials. Always verify that a specific PET-coated product matches the use conditions it is marketed for.

Environmental Impact of PET coated

Recycling Challenges Of PET Coated Materials

PET-coated paperboard and other composites may be rejected by standard recycling systems because the layers are hard to separate. Multilayer packaging remains a major challenge due to mixed materials, contamination, and limited processing capacity in many regions.

Alternatives to PET Coated

Depending on the application, alternatives may include:

- Water-based barrier coatings

- Bio-based coatings

- Mono-material redesigns that fit a single recycling stream

Eco-Friendly Innovations in PET Coated Materials

Innovation directions include:

- Delamination technologies that improve layer separation

- Chemical recycling pathways for PET in specific scenarios

- Design-for-recycling structures that reduce mixed-material complexity

How long does PET Film Last?

Durability of PET Film in Different Conditions

PET film is generally durable and can remain stable for long periods. Lifespan depends on UV exposure, heat and humidity cycling, chemical contact, and mechanical abrasion.

Longevity in Various Applications (Packaging, Textiles, etc.)

Typical expectations:

- Packaging: designed for months to a couple of years of shelf and handling life

- Industrial labels and overlays: can last years depending on environment

- DTF transfer films: the film is temporary, while print durability depends on inks, adhesives, and wash conditions

The Future of PET coated

Innovations and Trends in PET Coated Materials

Expect growth in recyclable mono-material packaging, thinner high-performance barrier layers, coatings engineered for easier separation, and advanced recycling pathways where they make environmental and economic sense.

Potential for Sustainability and Eco-Friendliness

The biggest sustainability wins will come from better system design: packaging that matches local recycling capabilities, simpler material combinations, and increased recycled content (where safe and allowed).

Conclusion

PET coated is a powerful packaging and materials technology because it boosts strength, barrier performance, and print quality across many substrates. But it is not automatically “green”—the environmental story depends on whether the final structure is recyclable in real-world systems, especially for PET-coated composites. The future is likely to favor design-for-recycling, smarter coatings, and innovations that preserve performance while reducing end-of-life complexity.