Paper Cup Fan

About Paper Cup Fan

Paper cup fans are used to manufacture paper cups. They are usually made of food-grade paper and may be coated with a thin layer of plastic or wax to prevent leaks or seepage of liquids.

Paper cup fans come in various sizes and thicknesses, depending on the size and shape of the paper cups to be made. The fan is loaded into a cup-making machine, where it undergoes a series of processes such as cutting, shaping, and sealing to create the final paper cup.

Paper fan for paper cups are commonly used in the production of disposable paper cups, which are widely used in the food and beverage industry. They are preferred over plastic cups due to their biodegradability and eco-friendliness. Additionally, using paper cup blanks allows for flexibility in the design and customization of paper cups, allowing for unique branding and advertising opportunities.

One-stop Service Available

Get all your paper packaging needs met with Sowineco’s one-stop service. Our range includes reels, cupstock, sheets, and paper cup fans. Equipped with state-of-the-art machinery like our flexo printing machine, Heidelberg UV offset printing machine, and die-cutting machines, we are your go-to for reliable and high-quality paper products.

Sowineco Provide Various Kinds Of Printed Paper Cup Fan

- Stable Supply

- Quality Assurance

- Free Sample Available

Sowineco Advantages

- Various printing method options available

- 7 colors, embossed, gold foil print and UV spot available

- Template design free

- Size customized available

- Food Contact Safety Certificate

FLEXO PRINTING MACHINE

UV Printing Machine

DIGGING OUT PAPER CUP FAN

DIE CUTTING MACHINE

CHECKING COLOR DIFFERENCE

PAPER CUP FAN WITH COMPETITIVE PRICE

30,000+MT

WAREHOUSE

Our advanced workshop and expansive 10,600 m² warehouse provide the capacity for a massive 30,000 MT production per month – ensuring that orders are met quickly and without interruption. With our production capacity constantly on the rise, we are well-positioned to meet any demand that comes our way.

Sowineco Service

- One-stop Service Available

Sowineco offer comprehensive business options ranging from all types of coating/lamination, paper cutting&printing to new material R&D, aiming to save considerable time, money and effort for you.

- Free Sample Available

If you’re interested in our products, please contact us right away and you can take your desired sample free of charge.

- Wholesale At Affordable Prices

Regardless of the order quantity, we sell our products wholesale at competitive prices, contributing to a significant reduction in your business costs and reduction on inventory pressure.

- Start With Low MOQ

Don’t worry about MOQ! If you’re hesitating because you don’t really know us, we can start with low MOQ or a trial order (one container to start).

- Fast Delivery

① Available in stock: The goods can be shipped immediately after receiving the order.

② No inventory: The average delivery time is about 5 weeks after receiving the order.

- Quick After Sales Response

If you encounter any problem related to after sales or have any suggestion for us, our professional team will be there for you 24*7 to be a good listener and offer you instant help.

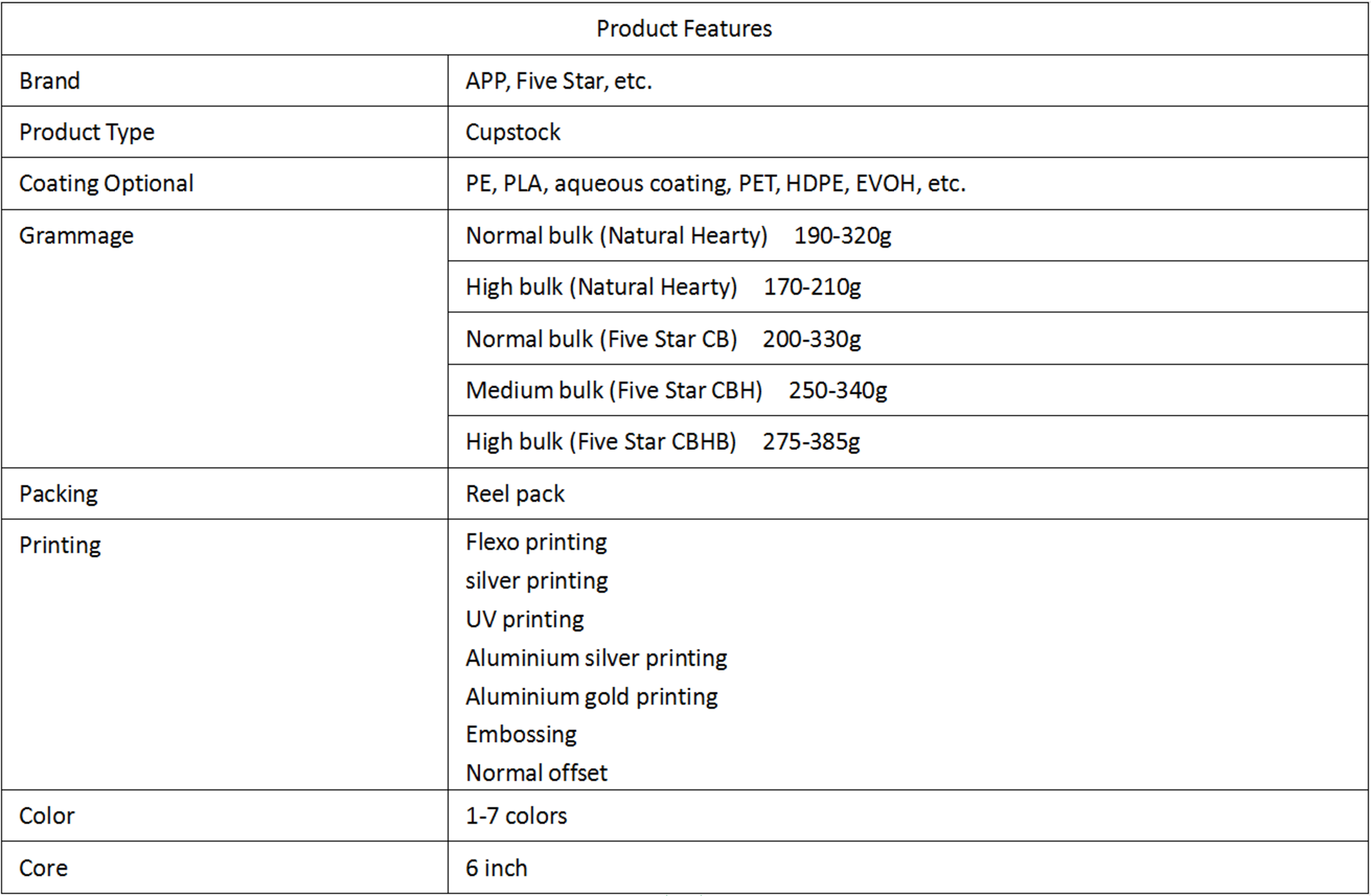

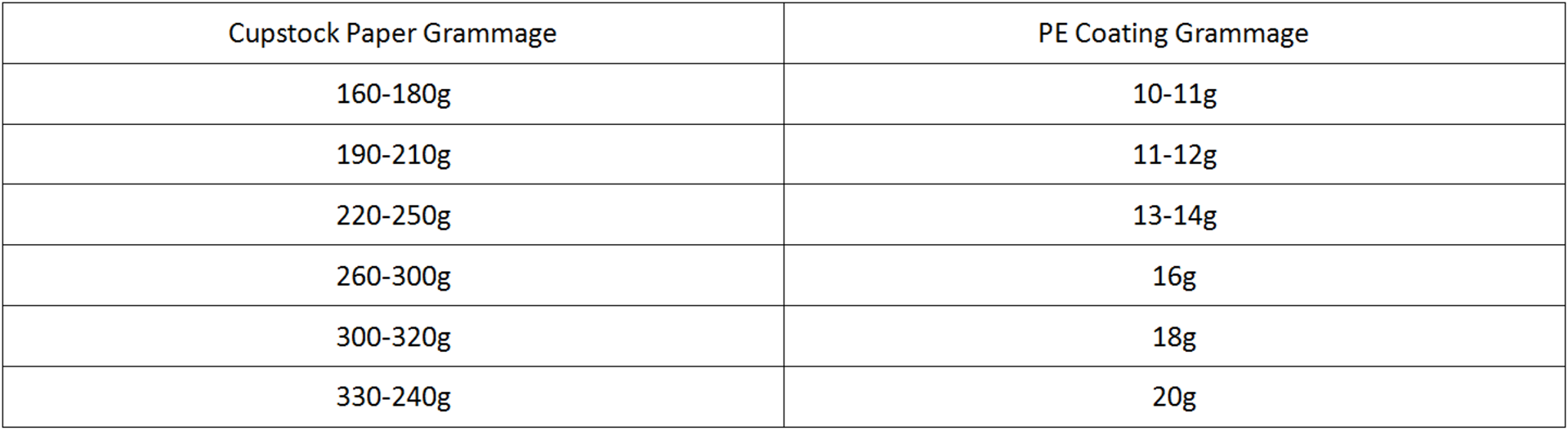

PAPER CUP FAN Product Datasheeet

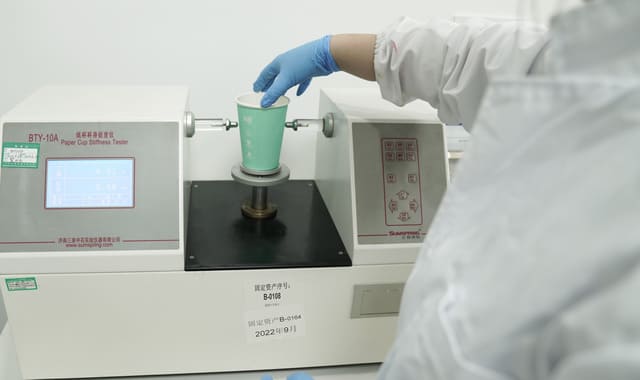

PAPER CUP LEAKAGE TEST

PAPER CUP STIFFNESS TEST

KRAFT CUPSTOCK STANDARD PACKING

QUALITY INSPECTION OF PAPER CUPS

QUALITY APPRAISAL OF PRINTING

The global demand for paper cups has been increasing steadily, mainly due to the growing trend of take-out food and drink consumption. Paper cup machines have become a vital part of the consumer products manufacturing process. Cupstock is a key material used in paper cup machines that produce high-quality paper cups. In this blog post, we will delve into the versatility of cupstock and how it is used in paper cup machines to meet the demands of the food and beverage industry.

Firstly, let us understand what cupstock is. Cupstock is a food-grade paper that is used to manufacture disposable paper cups. It is made up of layers of bleached wood pulp that are combined with a waterproof coating material on one surface of the paper. This coated surface provides a barrier to prevent any liquid from penetrating the paper cup. This characteristic makes cupstock a popular choice among manufacturers of paper cups. They come in various weights and thicknesses depending on the requirements of the paper cup machines.

Secondly, a paper cup machine is a manufacturing machine that utilizes cupstock to produce paper cups. The process involves the feeding of pre-cut cup blanks into the paper cup machine, which then converts them into ready-to-use disposable paper cups. The machine cuts, folds, and seals the cup blanks with the help of heat and pressure. Paper cups are an eco-friendly alternative to plastic cups, making them a more sustainable option for the food and beverage industry.

Thirdly, cupstock can be customized to meet specific requirements, making it a versatile material. The coating material used on the paper surface can be adjusted to provide different levels of insulation, depending on the required heat retention of the beverage. The printing design on the paper cups can also be customized, making them ideal for branding and advertising. These customizations make paper cups an excellent marketing tool for businesses in the food and beverage industry.

Fourthly, paper cup machines are highly automated and efficient. They are designed to produce large volumes of paper cups with minimal human intervention. The machines also require minimal maintenance, ensuring reliable and consistent performance. The use of paper cup machines and cupstock has revolutionized the paper cup manufacturing process, making it faster, more efficient, and cost-effective.

Cupstock plays an important role in the paper cup manufacturing process. It ensures that paper cups are safe and efficient for consumers to use. The combination of paper cup machines and cupstock paper has transformed the paper cup industry, making it a sustainable solution for the food and beverage industry. Sowineco is committed to providing customers with high-quality cupstock and paper cup machine for the production of better, more sustainable paper cups. By using quality cupstock, we are contributing to a more sustainable future.