EVOH(High-Barrier) LAMINATION

ABOUT EVOH(High-Barrier) LAMINATION

EVOH high-barrier lamination film is renowned for its exceptional oxygen barrier properties, ideally extending the freshness and shelf life of sensitive products like food and pharmaceuticals. Combining high clarity, excellent aroma retention, and durability, it is the definitive solution for demanding applications including vacuum packaging of meats and cheeses, liquid products like sauces and juices, pharmaceuticals, and premium electronics packaging, where maximum protection is paramount.

Why choose Sowineco

Provide efficient and professional technical support to offer industry solutions for customers.

One-stop Service Available

Sowineco is committed to redefining the supplier-client relationship by offering a comprehensive, seamless partnership that guides your project from conception to completion. We offer one-stop services covering the entire process from customized solutions and rapid prototyping to mass production. Our manufacturing capabilities include, but are not limited to, coating, lamination, printing, hot stamping, slitting, die-cutting, and corrugated paper services. We are more than just a materials supplier – we are your trusted partner, dedicated to navigating your success through professional technical support and efficient delivery.

EVOH WITH COMPETITIVE PRICE

With a production capacity exceeding 30,000 tons per month, we have a competitive edge in the supply of paper cup raw materials, cupstock, and other similar products. This allows us to provide smaller volume packaging factories with enhanced and flexible service options that meet their needs. Choose us for the best solutions in the industry.

30,000+MT

Sowineco's EVOH ADVANTAGES

Our distinct advantage in the field of EVOH lamination lies in our mastery of its application to deliver superior value.

We excel through deep technical expertise, engineering custom film structures tailored to your product’s specific needs—such as moisture content, fat composition, and shelf-life goals—to precisely calibrate the barrier layer for optimal performance without over-engineering.

Utilizing state-of-the-art co-extrusion lines, we guarantee flawless lamination and strong interlayer adhesion, resulting in consistently high-quality, reliable output. Furthermore, strategic sourcing of prime resins and efficient, scaled manufacturing allow us to maintain rigorous quality control while achieving an exceptional price-to-performance ratio, making top-tier barrier protection both a reliable and cost-effective choice for your business.

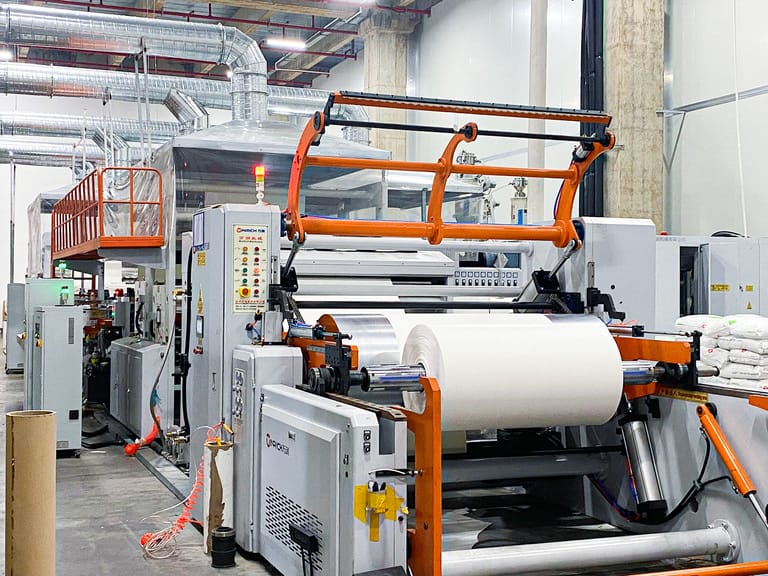

Coating Machine

Sowineco high-speed coating machine allows for precise and efficient applications of various coatings and laminates onto a range of different materials, ensuring we can meet all of our customers’ diverse requirements.

Printing Machine

The Heidelberg UV machine utilizes UV (Ultraviolet) technology to deliver superior print quality, productivity, and flexibility across various substrates, making it ideal for applications in cupstock.

WAREHOUSE

Our advanced workshop and expansive 10,600 m² warehouse provide the capacity for a massive 30,000 MT production per month – ensuring that orders are met quickly and without interruption.

Sowineco Service

- One-stop Service Available

Sowineco offer comprehensive business options ranging from all types of coating/lamination, paper cutting&printing to new material R&D, aiming to save considerable time, money and effort for you.

- Cupstock Free Sample Available

If you’re interested in our products, please contact us right away and you can take your desired sample free of charge.

- Wholesale At Affordable Prices

Regardless of the order quantity, we sell our products wholesale at competitive prices, contributing to a significant reduction in your business costs and reduction on inventory pressure.

- Start With Low MOQ

Don’t worry about MOQ! If you’re hesitating because you don’t really know us, we can start with low MOQ or a trial order (one container to start).

- Fast Delivery

① Available in stock: The goods can be shipped immediately after receiving the order.

② No inventory: The average delivery time is about 5 weeks after receiving the order.

- Quick After Sales Response

If you encounter any problem related to after sales or have any suggestion for us, our professional team will be there for you 24*7 to be a good listener and offer you instant help.

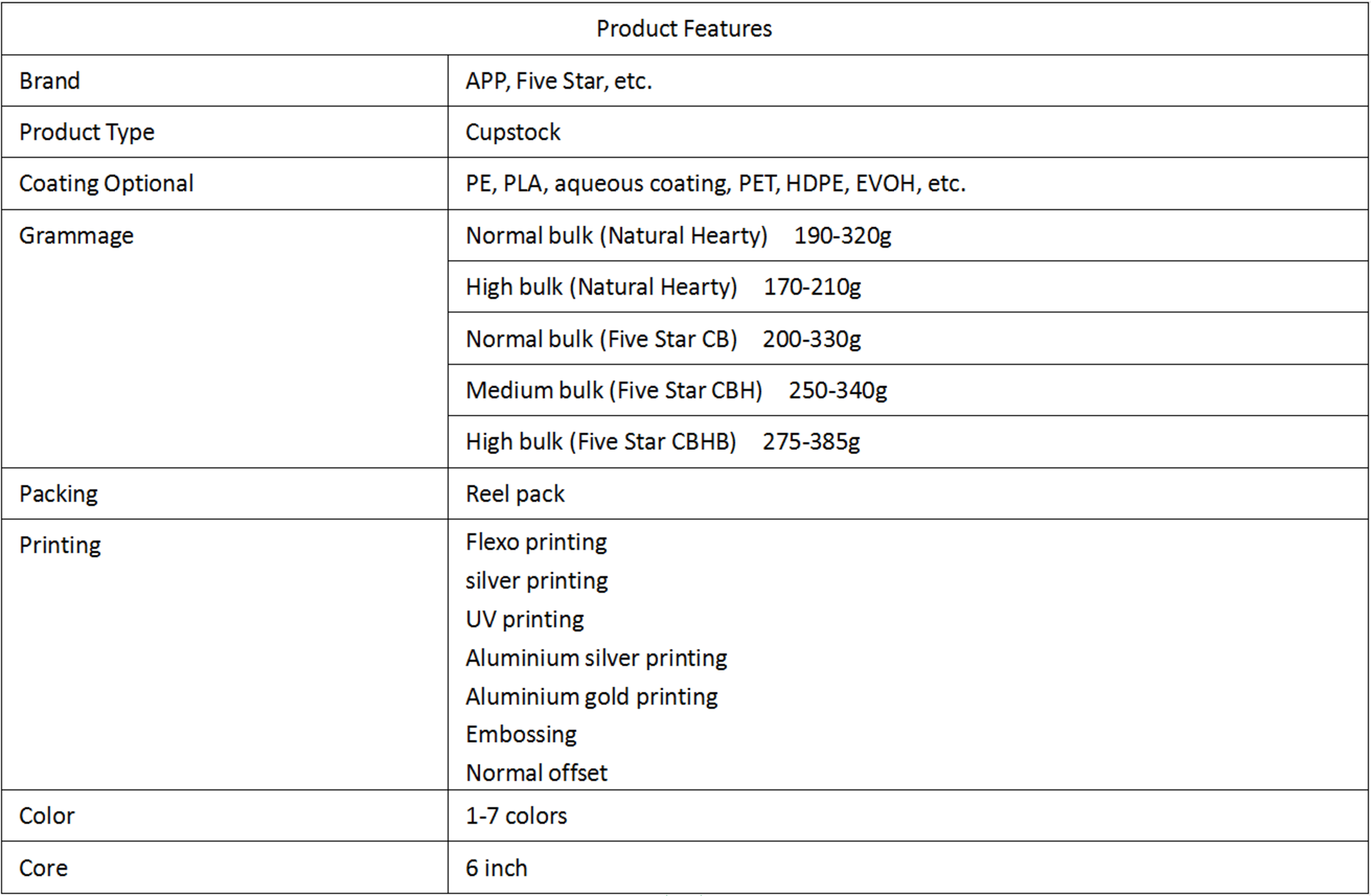

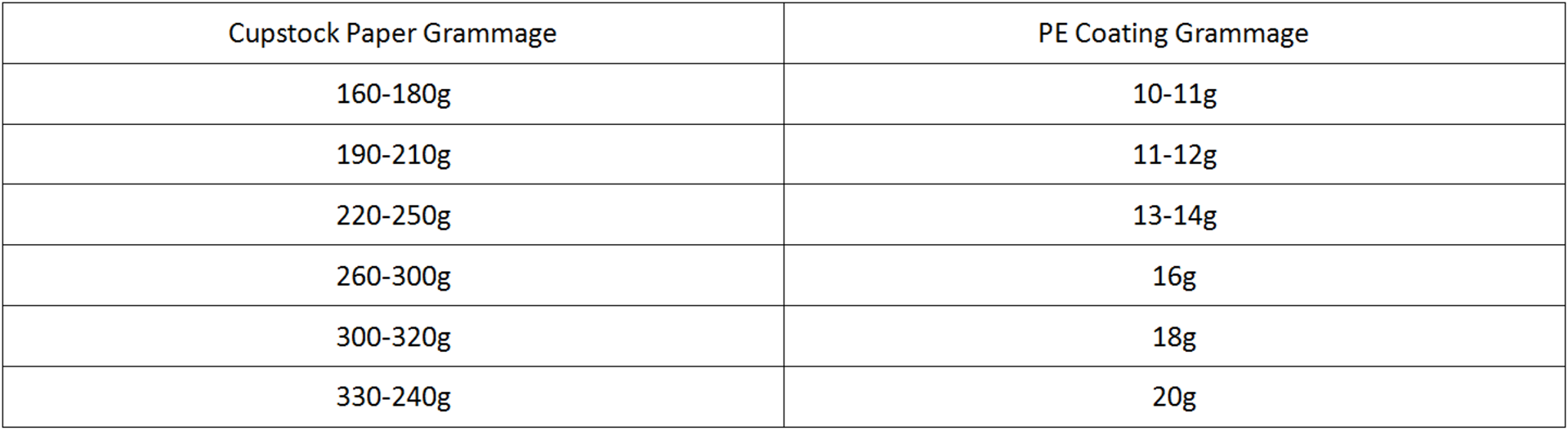

CUPSTOCK Product Datasheeet

PAPER CUP LEAKAGE TEST

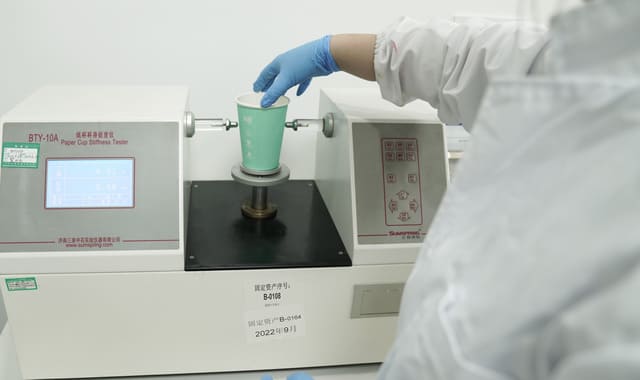

PAPER CUP STIFFNESS TEST

CHECKING COLOR DIFFERENCE

KRAFT CUPSTOCK STANDARD PACKING

HOW TO CHOOSE A RELIABLE CUPSTOCK SUPPLIER?

Choosing the right cupstock supplier can be a challenging task, especially when you are new to the packaging industry. A reliable cupstock supplier is necessary to ensure the quality and consistency of your products. However, with many suppliers available in the market, it can be difficult to know which supplier is worth your investment. In this blog post, we will guide you through the essential factors to consider when selecting a reliable cupstock supplier.

- Quality of the Products:

The first factor to consider when selecting a cupstock supplier is the quality of their products. Always select a supplier who provides high-quality and sustainable cupstock. Check if the supplier meets all the necessary certifications and requirements. Also, ask for a sample of their cupstock before making any purchase to guarantee the quality and consistency of their products.

- Pricing:

Before finalizing a cupstock supplier, do thorough research on the pricing offered by different suppliers. Consider the price, discounts, and other terms of the supplier to ensure that they provide competitive pricing. However, do not compromise the quality and consistency of the product just to save some money. Invest in a reliable supplier who provides good value for money.

- Turnaround time:

Another crucial factor to consider when selecting a cupstock supplier is their turnaround time. Ensure that the supplier you choose can meet your specific production requirements, including deadlines, delivery expectations, and other lead time considerations. Check their manufacturing capacity and reliability to guarantee that they can meet your business needs and expectations.

- Customer Service:

Selecting a cupstock supplier who provides excellent customer service is critical. A reliable supplier must be able to support you throughout the purchasing process, answer any queries, and provide solutions to issues. Check their communication channels and the quality of their customer service team, including response time, service quality, and professionalism.

- Reputation:

The reputation of the cupstock supplier is essential to consider when making a final decision. Check the supplier’s reviews online, including their website, social media, and other platforms. Check for the supplier’s testimonials, case studies, and their previous work for other customers. This will give you an idea of their reputation and the quality of their products.

By considering all these factors when selecting a cupstock supplier, you can ensure that your packaging meets the highest standards and that your customers are satisfied with your products. Sowineco is a reliable cupstock supplier that offers high-quality products, competitive pricing, fast turnaround times, excellent customer service, and a solid reputation. With Sowineco as your partner, you can focus on growing your business and providing the best possible experience to your customers. Contact Sowineco today to learn more about their cupstock solutions.

THE VERSATILE USE OF CUPSTOCK IN PAPER CUP MACHINES

The global demand for paper cups has been increasing steadily, mainly due to the growing trend of take-out food and drink consumption. Paper cup machines have become a vital part of the consumer products manufacturing process. Cupstock is a key material used in paper cup machines that produce high-quality paper cups. In this blog post, we will delve into the versatility of cupstock and how it is used in paper cup machines to meet the demands of the food and beverage industry.

Firstly, let us understand what cupstock is. Cupstock is a food-grade paper that is used to manufacture disposable paper cups. It is made up of layers of bleached wood pulp that are combined with a waterproof coating material on one surface of the paper. This coated surface provides a barrier to prevent any liquid from penetrating the paper cup. This characteristic makes cupstock a popular choice among manufacturers of paper cups. They come in various weights and thicknesses depending on the requirements of the paper cup machines.

Secondly, a paper cup machine is a manufacturing machine that utilizes cupstock to produce paper cups. The process involves the feeding of pre-cut cup blanks into the paper cup machine, which then converts them into ready-to-use disposable paper cups. The machine cuts, folds, and seals the cup blanks with the help of heat and pressure. Paper cups are an eco-friendly alternative to plastic cups, making them a more sustainable option for the food and beverage industry.

Thirdly, cupstock can be customized to meet specific requirements, making it a versatile material. The coating material used on the paper surface can be adjusted to provide different levels of insulation, depending on the required heat retention of the beverage. The printing design on the paper cups can also be customized, making them ideal for branding and advertising. These customizations make paper cups an excellent marketing tool for businesses in the food and beverage industry.

Fourthly, paper cup machines are highly automated and efficient. They are designed to produce large volumes of paper cups with minimal human intervention. The machines also require minimal maintenance, ensuring reliable and consistent performance. The use of paper cup machines and cupstock has revolutionized the paper cup manufacturing process, making it faster, more efficient, and cost-effective.

Cupstock plays an important role in the paper cup manufacturing process. It ensures that paper cups are safe and efficient for consumers to use. The combination of paper cup machines and cupstock paper has transformed the paper cup industry, making it a sustainable solution for the food and beverage industry. Sowineco is committed to providing customers with high-quality cupstock and paper cup machine for the production of better, more sustainable paper cups. By using quality cupstock, we are contributing to a more sustainable future.

QUALITY IDENTIFICATION OF CUPSTOCK

Cupstock is widely used in the food and beverage industry for its durability, moisture resistance, and printability. It is commonly used for making cups, plates, and other food packaging products. The quality of cupstock is determined by its thickness, weight, stiffness, and absorbency. In this article, we will discuss the factors that affect the quality of cupstock and the methods to identify it.

- Thickness: The thickness of cupstockis an important factor that determines its quality. The thickness of cupstockranges from 150 to 400 gsm (grams per square meter). The higher the gsm, the thicker the paper. The thickness of cupstock is measured using a micrometer. The micrometer measures the distance between the two plates that press the paper. A high-quality cupstock has a uniform thickness.

- Weight: The weight of cupstockis another factor that determines its quality. The weight of cupstockranges from 150 to 400 gsm. The weight of cupstock is measured using a weighing scale. A high-quality cupstock has a uniform weight.

- Stiffness: The stiffness of cupstockis another factor that determines its quality. The stiffness of cupstockis measured using a stiffness tester. The stiffness tester measures the force required to bend the paper to a certain angle. A high-quality cupstock has a high stiffness, which makes it easier to handle.

- Absorbency: The absorbency ofcupstockis another factor that determines its quality. The absorbency of cupstock is measured using a Cobb tester. The Cobb tester measures the amount of water absorbed by the paper in a certain period. A high-quality cupstock has a low absorbency, which makes it suitable for food and beverage packaging.

- Printability: The printability ofcupstockis another factor that determines its quality. The printability of cupstock is determined by its surface roughness and ink absorption. A high-quality cupstock has a smooth surface and high ink absorption, which makes it easy to print on.

The quality of cupstock is determined by its thickness, weight, stiffness, absorbency, and printability. A high-quality cupstock has a uniform thickness and weight, high stiffness, low absorbency, and smooth surface with high ink absorption. The methods used to measure these factors include a micrometer for thickness, a weighing scale for weight, a stiffness tester for stiffness, a Cobb tester for absorbency, and surface roughness and ink absorption for printability. By identifying the quality of cupstock, we can ensure that it meets the requirements for food and beverage packaging.